You spend a lot of money on your plastic injection molds. Maintaining and repairing them can keep them running for years, providing a valuable return on your investment.

Short of a mold totally crashing, how do you know when a mold needs repair or maintenance? This article will tell you. We identify plastic part defects that can be signs of mold repair and maintenance. This article is part of a series discussing injection mold maintenance and repair.

Signs That Your Injection Mold Needs Repair or Maintenance

How do you know when a mold needs maintenance or repair? Short of a complete failure, here are the 7 tell-tale signs to look for in the parts that are produced by the mold.

- #1: Short shots where parts are ejected in an incomplete state

- #2: Burrs and flashing caused when excess plastic seeps into gaps in the mold

- #3: Flow marks caused by uneven injection speed or cooling

- #4: Blistering, stress cracks, and burn marks brought on by prolonged exposure to high temperatures

- #5: Drag marks caused by a misaligned ejector system

- #6: Voids or depressions from non-uniform heating or cooling of materials

- #7: Streaks

I this article, we discuss warning sign #5, Drag Marks.

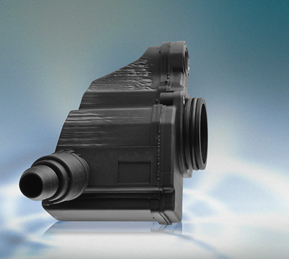

Injection Mold Warning Sign #5: Drag Marks

If your part has scratches or gouges in its surface, this may be a sign that the part is dragging against the mold cavity walls as it is being ejected. This can happen when the draft angle is insufficient to accommodate shrinkage and ejection or the mold’s surface finish is perpendicular to the release direction.

If your part has scratches or gouges in its surface, this may be a sign that the part is dragging against the mold cavity walls as it is being ejected. This can happen when the draft angle is insufficient to accommodate shrinkage and ejection or the mold’s surface finish is perpendicular to the release direction.

This often means that a redesign and adjustment to the part and mold must be made to increase the draft angle or change the position of the parting line.

Choose an Injection Mold Maintenance and Repair Partner You Can Trust

Why choose MPP? When you choose MPP, you get:

- A team of mold builders who have a combined 100+ years of mold building experience

- Expert knowledge of plastics and manufacturing processes

- In-house engineering and design services from experienced engineers

- In-house repair and maintenance from skilled mold builders, welders and machine operators

- A Quality Assurance system that meets all requirements of the ISO 9001:2008 Quality Assurance Standard

- Pickup and delivery from anywhere, anytime

- Personalized solutions

To discover how we can help you, call 810.364.2939 or contact us.